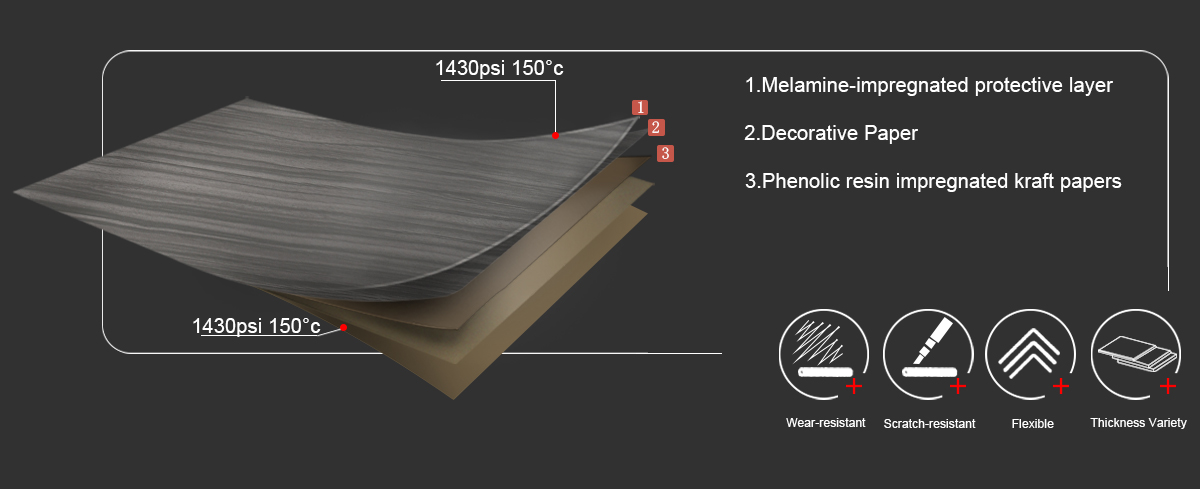

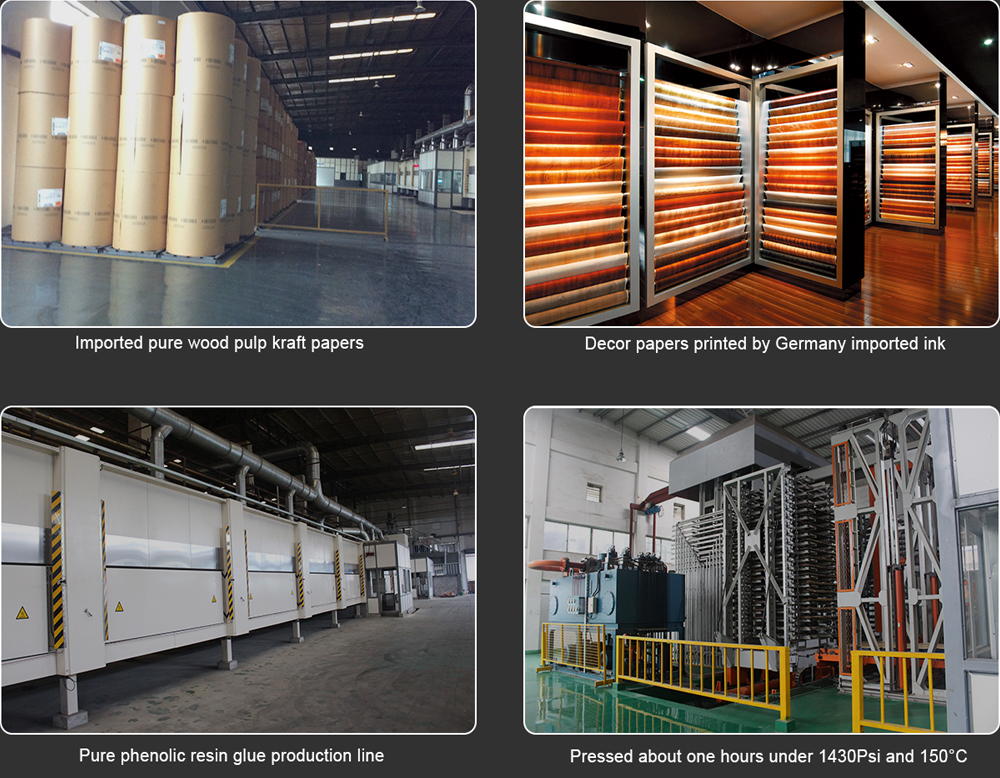

Greenia Laminates are composite with imported decorative paper soaked with melamine resin and a multilayer of imported kraft paper soaked with phenolic resin. The decorative paper and kraft paper will be compressed continuously and uniformly by the Germany thermal compressor for more than one hour.

Greenia laminates are mainly served as indoor decoration. For instance, office furniture, ceiling, cabinet, door, desktop, partition, etc.

| Type |

Flat Laminate |

Post-forming Laminate |

|

Common Thickness |

0.8mm |

0.7mm |

|

Common Size |

4'x8' (1220x2440mm) |

|

|

4'x10' (1220x3050mm) |

||

|

Laminate physical performance |

0.8mm fiat laminate | 0.7mm postforming laminate | 1.0mm flat laminate |

| Greenia Typical Value | NEMA standard |

NEMA standard |

|

| High Temperature Resistance | No effect | SL-Slight effect | SL-Slight effect |

|

Cigarette Resistance |

No visible change |

SL-Slight effect |

SL-Slight effect |

| Ball Impact Resistance |

Height of impact resistance: 1025mm |

≥500mm No change |

≥900mm No change |

|

Light Resistance |

No effect |

No effect |

No effect |

|

Scratch resistance |

2N |

≥1.5N |

≥1.5N |

|

Abrasion Resistance |

≥400 cycles |

≥400 cycles |

≥400 cycles |

|

Dimensional Stability |

|

|

|

|

Machine Direction |

|

1.1%(max.) |

0.6%(max.) |

| Cross Direction |

|

1.4%(max.) |

1.0%(max.) |

Note: NEMA Note: NEMA LD3:2005 is the national standard for high-pressure decorative laminate in the United States. Please read it carefully on the Greenia company website before using it. Website: www.greenia-hpl.com

The typical value doesn't represent the product performance specification. The typical value may be different for different surfaces and decor papers. The values above are tested by SGS-CSTC Standards Technical Services Co., Ltd. If you need the test certificates, please contact our sales manager or call Greenia company at 0086-755-23354285.

High-pressure laminates are subject to flame spread index (FSI) and smoke-developed index (SDI) in structures where codes establish such conditions.

Since the tested sample received a Flame spread index of 15 and Smoke Developed index of 20, it would meet the requirement of the Class A interior Wall & Ceiling Finish Category. The burning behavior test method is in accordance with ASTM E84:2011b Standard Test Method for Surface Burning Characteristics of Building Materials.

Typical values for Greenia laminates below are averaged from two specific tests:

|

Test ltem |

Greenia Typical Values |

The classes of flame spread index (FSI) and smoke- developed index in ASTM E 84 or UL 723 |

||

|

Class A |

Class B |

Class C |

||

|

Flame Spread Index (FSI) |

15 |

0-25 |

26-75 | 76-200 |

|

Smoke-developed Index (SDI) |

20 | 0-450 | 0-450 | 0-450 |

| Note: Above datas are tested by SGS-CSTC Standards Technical Services Co., Ltd. |

|

|||

high quality products at competitive price and best service to our customers.